Environmental and

Mechanical Testing Chamber.

Flexible hoses are used in a wide variety of environments.

Engine air intake and cooling water hoses in particular are subject to extremes of

temperature and vibration.

A hose manufacture required a test rig in which samples of hoses could be

subjected to continuous temperatures cycles, ranging from -50°C to 250°C. At the

same time the hoses were to be pulse pressurised at up to 5 bar, with both hot and

ambient air, and continuously flexed at up to 15 Hz.

The hoses are mounted inside an environmental test chamber which can

accommodate two to four hoses.

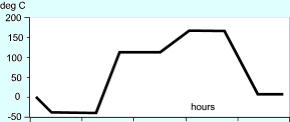

A temperature cycle typically consists of several ramps between the defined

temperatures with dwells at each temperature; the duration is generally several

hours. The cycle is repeated continuously throughout the duration of the test.

The pressure is applied to the hoses in

short pulses of a few seconds duration.

A system has been developed in which all these cycles can be flexibly programmed

to run asynchronously for continuous periods of up to several weeks in duration.

Test sequences can be scheduled to cover all combinations of temperature, pressure

and mechanical cycling.

As well as controlling the operation of the oven, the variable speed motor, and the

pressure cycles, the computer system monitors that the required test temperatures

are being achieved inside the hoses and that the required test pressure is being

achieved.

A full test log is maintained and regular test progress reports are generated.

Algorithms are incorporated to detect failure of the hose; if this should occur then

the system is automatically shut down and the failure condition noted.

The system was installed in 2001, with subsequent service visit in 2009.

One end of the hoses is fixed and the

other is connected to a motor driven

crankshaft via a connecting rod which

passes through seals in the floor of the

environmental chamber.